Power distribution systems and modules for control cabinets

Do you wish to optimise your power distribution system for AC or DC applications to meet your specific requirements? We offer you a comprehensive portfolio for all application areas such as high currents up 600 A or low current, modules for control cabinet installation, 19” solutions or track-mountable solutions and printed circuit boards.

We use basic E-T-A elements of our modular construction kit to build up the desired tailor-made solution. Requirements of the application will be implemented by resorting to components that already exist. This allows profitable solutions even for low volumes and in a short development time.

- Selective protection of load channels by means of plug-in type circuit breakers

- Load currents from 0.05 ... 125 A

- Typically up to 30 load circuits per distribution system

- Typical design as a 19” rack, module for installation in control cabinets, track-mountable

- Redundant and non-redundant versions

- Redundant supply with integral de-coupling diodes

- Group signalling via potential-free contacts

- Cable management and various connection technologies

- Voltage indication, voltage monitoring and current indication

- Profibus, ProfiNet or I/O link connection for remote control and diagnosis

Solution examples:

-

Chemical, petrochemical and pharmaceutical industry

Chemical, petrochemical and pharmaceutical industry

Request: Water supply in a chemical park

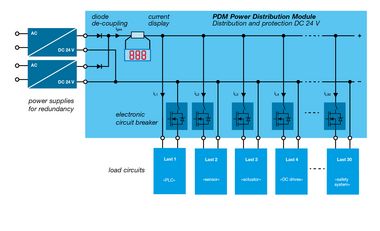

Many load circuits, long load lines, maximum availability - these are the requirements of the chemical industry regarding a power distribution and protection system for DC 24 V.

- Power supply with protection of the load circuits by means of electronic circuit protectors for sensors, actuators and control units in the field allows selective protection of the loads.

- Solution with plug-in type circuit breakers for fast and simple retrofit

- Group signalisation for remote signalling when circuit breaker tripped

- Redundant supply from two sources by including de-coupling diodes

- Recording and display of total current per distribution box

- Clear cable arrangement on terminal level replaces standard cable conducts

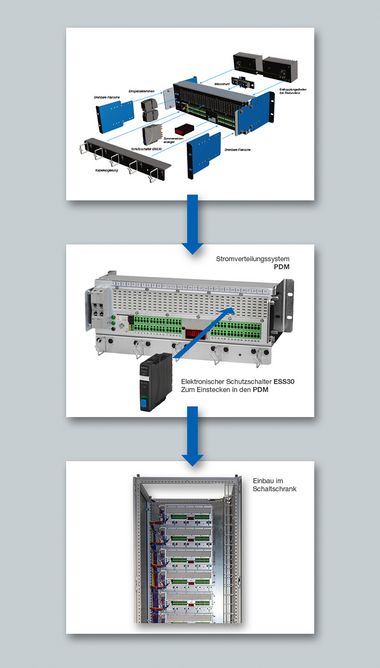

Solution: Power Distribution Module (construction kit system)

Basic elements from the existing construction kit are assembled to have the required customer-specific solution:

- Application requirements are met by consideration of existing components

- Economic solution even with small quantities

- Shortest design periods

The result is a power distribution module for 30 load circuits. This can be mounted alternatively onto the mounting plated of the control cabinet or into a 19” rack. Plug-in type electronic circuit protectors selectively protect the individual load circuits (sensors, actuators, control technology) even with long connecting cables.

Supply up to 80 A is redundant and has integral de-coupling diodes as well as a display of total current. All terminals are accessible from the front, the connecting cables are arranged via cable organizers on terminal level.

For the actual application in the system, three power distribution units each were installed in a control cabinet. The remaining free space already holds symmetrical rails and cable organizers for a later system extension on site with electronic components of the customer. Equally, the supply terminals in the lower part of the control cabinet are already populated and pre-wired.

-

Car production / other plants

Car production / other plants

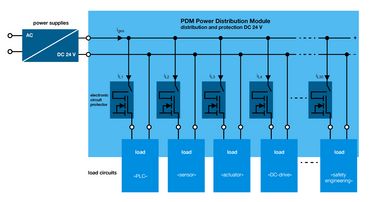

Request: Decentralised power supply via control of a production cell

Typical requirements include compact design with high protection degree, protection of many load circuits with high power and high uptime combined with a long life span and maintenance-free design.

- Installation on site with AC supply 400V

- Integral 40A power supply for DC24V

- Buffer module for possible voltage dips for full power

- 20 load circuits can be connected via spring-loaded terminals

- Interchangeable circuit breakers provide flexibility

- Failure indication in the event of trip of failure of components

- Compact design, high degree of protection and suitable for continuous duty at high ambient temperatures

Solution: Decentralised power distribution

- Power supply module for wall mounting on site with 3-phase AC supply, 24V power supply with 960W and buffer module for short power failures

- Selective protection of the load circuits by means of plug-in type, electronic circuit breakers for quick and easy retrofit

- Group signalling for remote signal when the circuit breaker has tripped

- Installation in a metal wall enclosure IP65 for maintenance-free continuous service at ambient temperatures up to +45°C without additional cooling

-

Power plant

Power plant

Application example: Monitoring in a power plant

In a nuclear power plant, sensors for monitoring of impact sound, vibrations, humidity, leakage, material fatigue and for the diagnosis of dashboards and rotating machines need to be supplied with various DC voltages.

- Protection of all DC and AC loads in the monitoring system

- Solution with plug-in type circuit breakers for fast and simple retrofit

- Group signalisation for remote signalling when circuit breaker tripped and components failed (power supplies).

- Redundant power supplies with downstream de-coupling diodes

- Compact design in 19” rack with rear-side connectors for easy and quick replacement of the entire sub-assembly.

Solution: Modifiable 19” rack in 3 versions

- 19 inch basic rack, built with components of the existing construction kit, with AC230V distribution (circuit breaker type 2210) and DC24V distribution (circuit breaker type ESS30).

- Various power supplies and DC-DC converters can be installed, which leads to creation of 3 different modules.

- Outer dimensions, terminals and basic functions, however, are always identical.

- This allows profitable solutions even for low volumes and in a short development time.